Five-axis linkage machine tool is a typical "three high" mechanical equipment -- high technology content, high precision and high cost. It has a decisive influence on a country's high-end manufacturing industry, and also has a variety of applications in the field of automobile manufacturing.

In the field of automobile processing, we provide processing equipment for Mercedes-Benz, BMW, Volkswagen, Audi and other well-known automobile brands, and have mature automobile processing solutions.

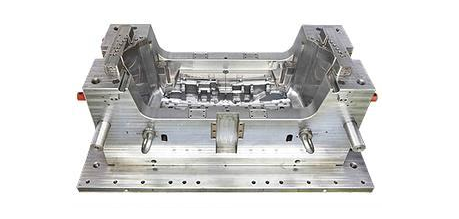

Die part

Many auto body sheet metal parts need stamping die, and because of the need of accessories, high precision requirements.

In the traditional die processing, it is commonly used to complete the milling of the workpiece by the three-axis machining center.

So why upgrade to a five-axis?

Five axes is the cost reduction option

Once clamping, multi-sided processing:

Processing will not occur interference, a clamping can be completed processing, and avoid repeated positioning error caused by multiple clamping. Not only the time is shortened, but also the large cost of the fixture required to install the workpiece is saved.

Headlamp mould

Reduce the cost of equipment investment:

Reduce workshop footprint and workshop number. A five - axis namely with turning, milling, drilling, grinding and other processes. Engineering intensive production only needs the pre-commissioning time, only need to import the blank data can complete the programming, but also can greatly shorten the pre-preparation.

Headlamp mould

Five axis machining precision is higher

Machining of deep cavity mold

When processing deep cavity, three-axis machining center must be lengthened shank and tool, but the use of five-axis machining center can be through the workpiece or spindle additional rotation and swing, so that the length of the tool can be shortened properly, so as to eliminate the collision phenomenon between the tool and the tool bar and the cavity wall, reduce the jitter and damage of the tool during processing, the service life of the tool is extended, The surface quality and processing efficiency of the mold are also greatly improved.

Bumper mold

Machining of die side wall

When processing the side wall, the length of the three-axis machining center tool is larger than the depth of the side wall, and the strength of the length of the tool will be significantly reduced. If the length of the tool is higher than 3 times the diameter, the quality of the tool phenomenon will be difficult to ensure. The five-axis machining center can make use of the swing of the spindle or the workpiece, so that the tool and the die side wall always present a vertical state, improve the quality of the workpiece and extend the service life of the tool.

Bumper mold

Flat surface machining of mold

When the surface is relatively flat, the three-axis machining center needs to increase the cutter path with the ball knife finishing milling, but the center rotation line speed of the ball head cutter is almost zero, the degree of damage to the tool is larger in the mold processing, the service life will drop sharply, the surface quality will become worse. The application of five axis machining center can be processed at a certain Angle, increase the relative linear speed, not only improve the service life of the tool, the workpiece surface quality will also be greatly improved.

Bumper mold

TITAN-B five axis mold processing center, using the German original five axis head and spindle, machine structure for double motor double screw structure, can be competent for die steel, stainless steel and other materials of fine mold processing.

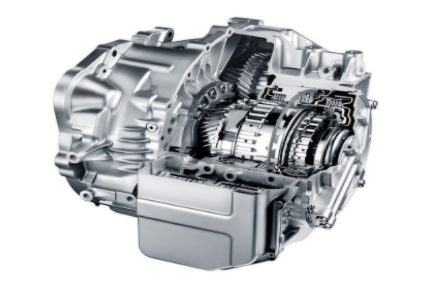

Engine section

Automobile engine is the device that provides the power for the automobile, is the heart of the automobile, determines the power, economy, stability and environmental protection of the automobile.

Automobile engine

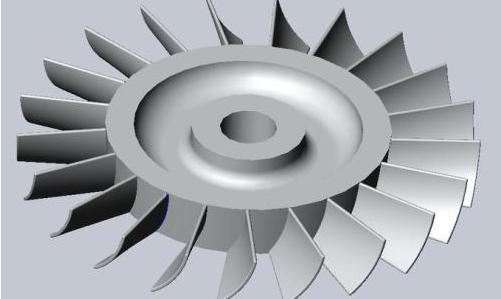

Take the engine impeller as an example. It is the core component of the displacement suffix "T" of the automobile. Its function is to rotate at a high speed and pressurize the engine cylinder to generate more power.

Engine impeller

The cylinder block is the shell and assembly basis of the engine. It is generally made of high-quality alloy cast iron or aluminum alloy. The cylinder wall should have effective high machining accuracy and low surface roughness.

Engine cylinder

Due to the large amount of processing and the same number of parts to be processed, Itley SKY horizontal conversion series can be divided according to the structure of the processing area, through the system to set the turntable rotation Angle and milling head Angle, a clamping multi-point processing.

Automobile industry is a huge social economic system engineering, different from ordinary products, automobile products are a highly integrated final product. Our complete five-axis machining series will also help the further development of the automotive industry.

电话

+86 13761797753

微信

微信二维码