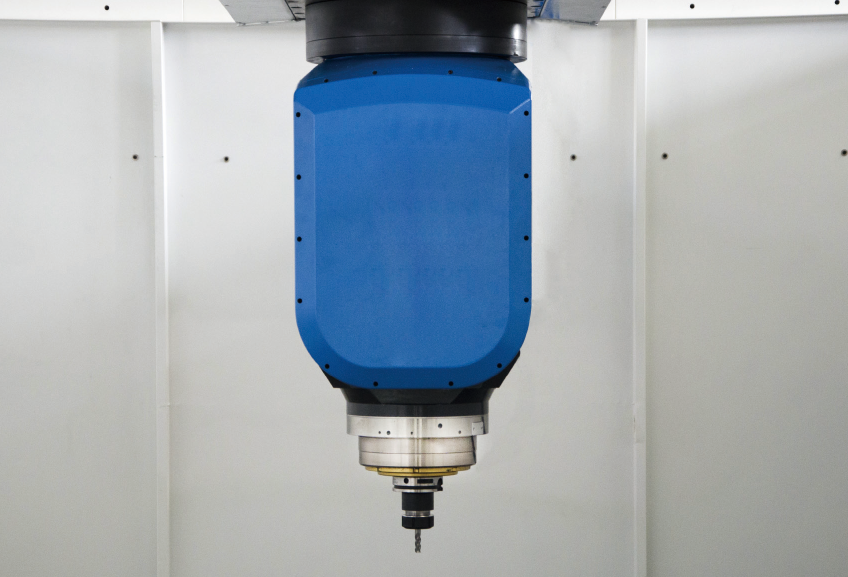

Five-axis CNC machining is a very important part of CNC machining, this technology has been widely used in the automotive, light industry, medical, shipbuilding, aerospace, and other high precision instrument manufacturing fields. In the traditional die machining, three axis machining center and vertical machining center are commonly used to complete the workpiece milling processing. With the continuous development of mould manufacturing processing technology in our country, some weaknesses of the traditional three-axis machining center and vertical machining center also gradually appeared. For example, in the current mold processing is more commonly used ball end milling cutter, the advantages of using ball end milling cutter in mold processing is obvious, but if used in vertical machining center, the bottom surface linear speed is zero, finish is poor, such as through the five axis machining center of the mold processing, the above shortcomings can be completely overcome.

1. Advantages of five-axis processing

In five axis machining, the use of flat end milling cutter to maintain the vertical state of complex die machining surface, to reduce the processing time is of great help. Based on the principle of five-axis machining center, it is also applicable to the side milling of the surface with an Angle, which can eliminate the rib ridges caused by the ball end milling cutter processing, making the surface quality of the mold more ideal, but also reduce the need to increase the manual milling and manual work for cleaning the surface of the mold, reducing a lot of costs.

Through the five-axis processing technology, can also make the workpiece in the complex Angle positioning need to be adjusted for many times to solve the problem of clamping, not only shorten the time, the error is also greatly reduced, in the installation of the workpiece need tooling fixture cost has been saved, and the machine tool has also done the processing of complex parts! For example, drilling, taper machining, cavity recess and so on are required for complex surfaces, which can not be done by traditional machining methods.

The tool used in the five-axis processing is shorter, but also can be a one-time processing of the whole part, no need to install the card again or use the same kind of three-axis processing in the need of longer tools, can be completed in a short time to make the mold, and the quality of the surface of the parts is better.

2, the application of five axis machining center in automobile mold processing

At present, the design of automobile parts mainly uses CAD system, and through reverse engineering and various tests to complete the design of parts, machining the complex surface of the mold using CAM software, but, how to ensure the design and processing accuracy? This is to rely on numerical control machining, the following five axis machining center in the mold processing of the application of the relationship between the quality of the automobile mold for some simple analysis.

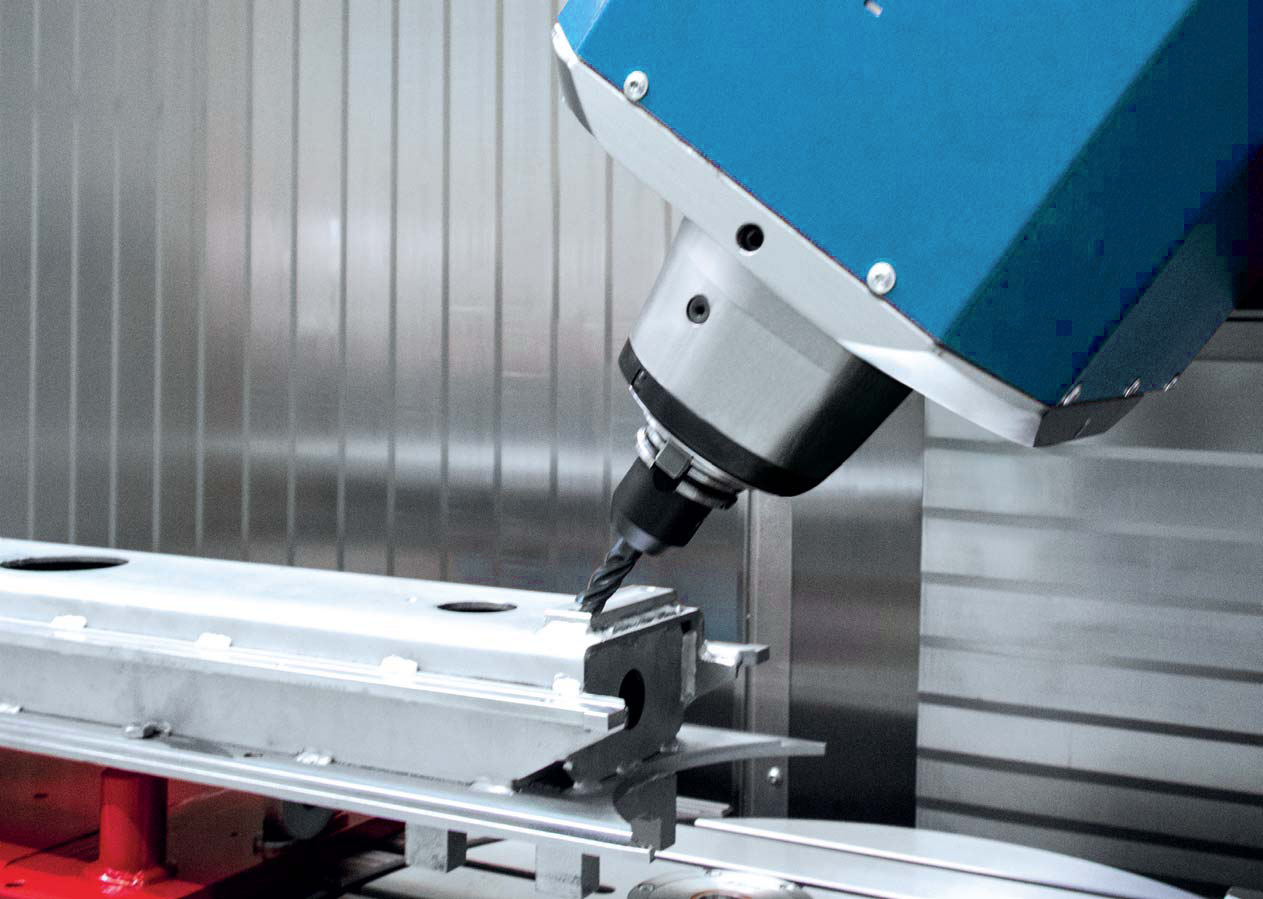

2.1 Processing of deep cavity mold

In the process of automobile mold manufacturing, processing deep cavity mold to the application of three axis machining center, it must be lengthened the handle and tool, but the use of five axis machining center processing deep and steep cavity, in order to create better technological conditions for mold processing can be through the workpiece or spindle head additional rotation and swing, can make the length of the tool can be properly shortened, In order to eliminate the collision phenomenon between the tool and the tool bar and the cavity wall, reduce the jitter and damage of the tool during processing, the service life of the tool is extended, the surface quality of the mold and the processing efficiency is also greatly improved.

2.2 Machining of die side wall

The processing of the mold side wall, the application of three-axis machining center tool length is larger than the depth of the side wall, but also by the depth of the side wall to determine the length of the tool, if increasing the length of the tool, its strength will be significantly reduced, if the tool length is higher than 3 times the diameter, so that the tool phenomenon will occur, the quality of the workpiece will be difficult to ensure. Such as the application of five axis machining center on the side of the mold processing, can use the spindle or workpiece swing, so that the tool and the mold side wall always present a vertical state, milling mold side wall can use the plane milling cutter, which can improve the quality of the workpiece and extend the service life of the tool.

2.3 Surface processing of relatively flat mold

When machining the flat surface of the mold, the three-axis machining center needs to be polished with the ball knife to obtain good surface quality, and in this case, the tool path needs to be increased, but the center rotation line speed of the ball head knife tool is almost zero, the degree of damage to the tool is larger in the mold processing, the service life of the tool will decline sharply, and the surface quality of the mold will become worse. Application of five-axis machining center processing surface, can be on the workpiece the tool into a certain Angle and then workpiece processing, so that can increase the workpiece and the ball head tool between the relative linear speed, not only can make the service life of the tool is improved, the surface quality of the workpiece will be greatly improved.

2.4 Machining the irregular surface of the mold

For mold processing with irregular surface, it is generally completed by three-axis machining center in the past, the direction of cutting tool mold is along the whole path of cutting to move the cutting process will not change, then the cutting state of the tool tip can not ensure the perfect quality of each part of the mold. Like the mold whose curvature changes more frequently and the mold with deeper grooves

Can be processed through the five-axis machining center, cutting tool can always make the cutting state to achieve the best, the tool can make the direction of the entire machining path to get the maximum optimization, and the tool in this at the same time can also make linear motion, the surface of the mold in each part will be more perfect.

2.5 Processing of different geometric shapes of molds

The application of five axis machining center to the three-dimensional curve plane of the mold processing, the cutting of the mold has always been protected in the best working state, the working Angle of the tool can be changed in any area of the machine tool processing, so as to complete the processing of the geometric mold.

2.6 Processing of inclined holes on mold inclined plane

If you want to milling no change of direction of a straight line, as long as the tip of a straight line can be, if the direction needs to change, the tip of a curve can be, the direction of the tool tip is changed, then want a straight line, it is necessary to give this curve compensation, the application of five axis machining center this is very important. If the control system does not take into account the length of the tool, the tool is rotated around the center of the shaft, the tool tip can not be fixed, it is very likely to move out of the current working position, but in the five-axis machining center system with five-axis control function, in the operation of the machining mold, the use of five-axis control system although the direction of the tool is changed, However, the position of the tool tip can be kept unchanged. In this process, the necessary compensation motion of xyz axis is also automatically calculated, and the machining accuracy is obviously improved.

In short, in the mold processing, the application of five axis machining center can avoid the interference of the tool, can be processed on the ordinary three-axis machine tool difficult to process complex parts, the processing of the straight surface mold, can use the side milling type of knife forming technology, processing quality is good, high efficiency. For vertical surface, especially the large flat surface processing, can be processed by large diameter end milling cutter end close to the large surface, the cutting times will be reduced, the residual height is small, processing efficiency and surface quality can be effectively improved. Multiple space surfaces of the mold can be clamped at one time to carry out multi-process and multi-surface processing, which improves the processing efficiency and also effectively improves the precision of each surface position. Application of five axis machining center for mold processing, for the workpiece, the tool can always be in the most effective cutting state, in some processing fields, can take large size tool to avoid mutual interference, the rigidity of the tool is better, processing accuracy and processing efficiency can be improved.

Therefore, the five-axis machining center has a wide range of processing adaptability and is worth popularizing.

电话

+86 13761797753

微信

微信二维码