Our Profile models, as the name suggests, is especially good at Aluminum profile processing (Aluminum profile), can be called profile processing "little bully", and at present, aluminum alloy structure vehicles have been widely used in railway vehicle EMU manufacturing and urban rail transit vehicle manufacturing, so debut so far, Profile has been in rail transit and other fields of aluminum alloy processing left a strong mark, including Zhongwang, Jilin Midas and other industry well-known enterprise customers praise!

And the story of Profile continues to be written, because for us, technological innovation, we never stop!

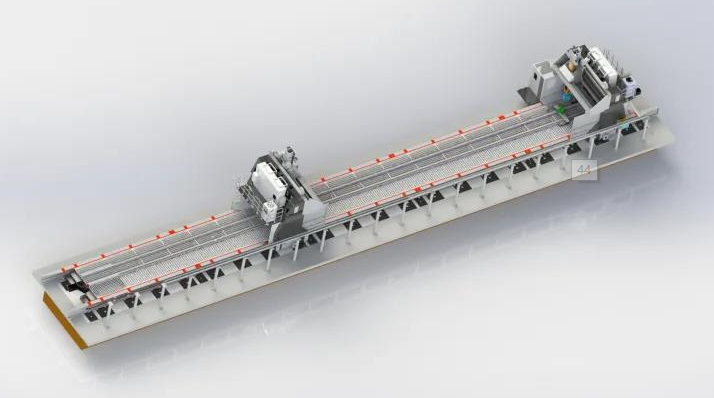

The picture shows the body machining site

This time, under the unremitting efforts of our scientific research team, our Profile successfully realized the double gantry structure, which means that the Profile models have achieved a set of rough processing and finishing dual functions in one, one gantry is responsible for rough processing, one is responsible for finishing, rough finishing process perfectly connected. Greatly improve the processing efficiency and cost, spend a share of money, buy a machine, do two things, save twice the time, but also save twice the manpower, simply too powerful.

Double gantry Profile models have the following advantages:

1. Long travel of X axis, large processing range, currently sold models of X axis travel up to 60 meters. In addition for long profile finishing, can be directly from the profile left and right synchronous processing, efficiency is 2 times of the conventional model.

2 double gantry structure, set fine rough processing in one, compared to the past first rough after fine processing procedures, double gantry structure can make fine processing and rough processing process perfect fit, seamless, at the same time, not only improve the processing efficiency, but also reduce the processing cost.

3. Automatic tool changing function, can be installed in the tool library for different purposes, a clamping through the automatic tool changing device to change the spindle machining tool, drilling, boring and milling, reaming, tapping, grooving and other processing functions, to complete the multi-surface or complex technology multi-process parts processing.

44 Picture shows a Profile model of double gantry

电话

+86 13761797753

微信

微信二维码