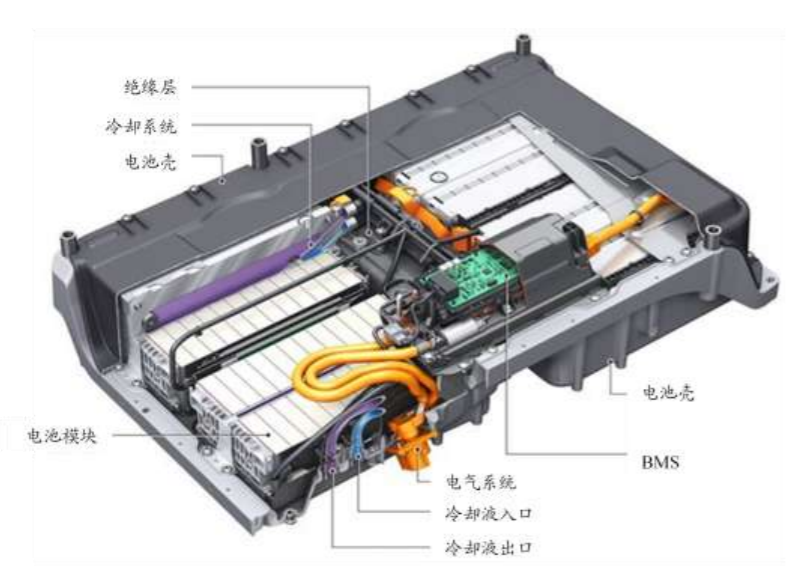

There is no doubt that the "bottleneck" link in the development of new energy vehicles is the new energy battery shell, which is the key because the new energy battery shell is like a "mother", covering the battery module, electrical system, thermal management system, shell and BMS and other core components. The so-called "stability is overwhelming", if the "mother" is unstable, its internal components will inevitably collide. In turn, it affects the stability and safety of the vehicle, so some enterprises will even integrate the battery shell and the body bottom plate to ensure stability.

The image shows the Audi Q7 e-tron battery system

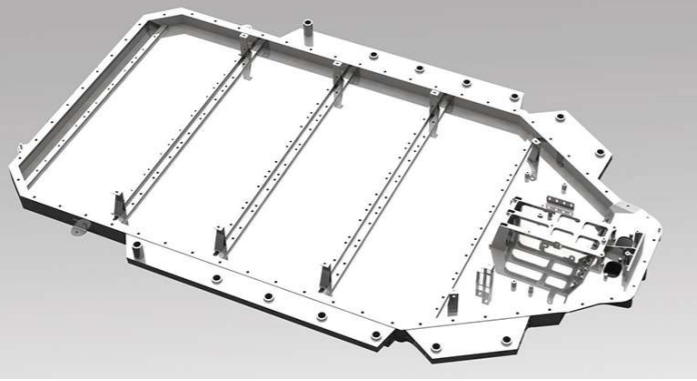

The picture shows the battery case (welded structure) of Lingyun Stock Company

So what does "stability" depend on? The hexagonal hole is one of the keys. Now the six square hole processing is no longer difficult, in short, its processing technology can be divided into two steps, the first step is in advance on the workpiece to turn out the appropriate diameter of the hole, and processing chamfer, as the punch guide hole; The second step is to change the shank with the punch, choose the right speed and feed speed processing; The third step is chamfering deburring. Usually, the punch is mounted on the handle at an Angle of 1 degree. The joint motion of rotation and swing during rotation can cut the profile of the tool.

However, although the process is simple, it cannot withstand the large number of hexagonal holes that need to be processed in the new energy battery shell, and the requirements for accuracy are high. Therefore, how to quickly and accurately process the hexagonal holes, improve the stability and safety of the new energy battery shell, and comply with the development trend of new energy vehicles still needs to cross the sea and show their abilities.

The picture shows a group of punches used for hexagonal hole machining

At the beginning of our establishment, we have accumulated a wealth of successful cases in the processing of new energy vehicle battery box, has provided machine tools for the battery case processing of Daimler, Minth, Lingyun, BMW Brilliance and other well-known enterprises, according to the different processing needs of customers, fast, accurate, continuous processing of six square holes in large parts, to help customers of the battery case production line processing efficiency needs, In the new energy battery shell industry left a strong pen.

电话

+86 13761797753

微信

微信二维码